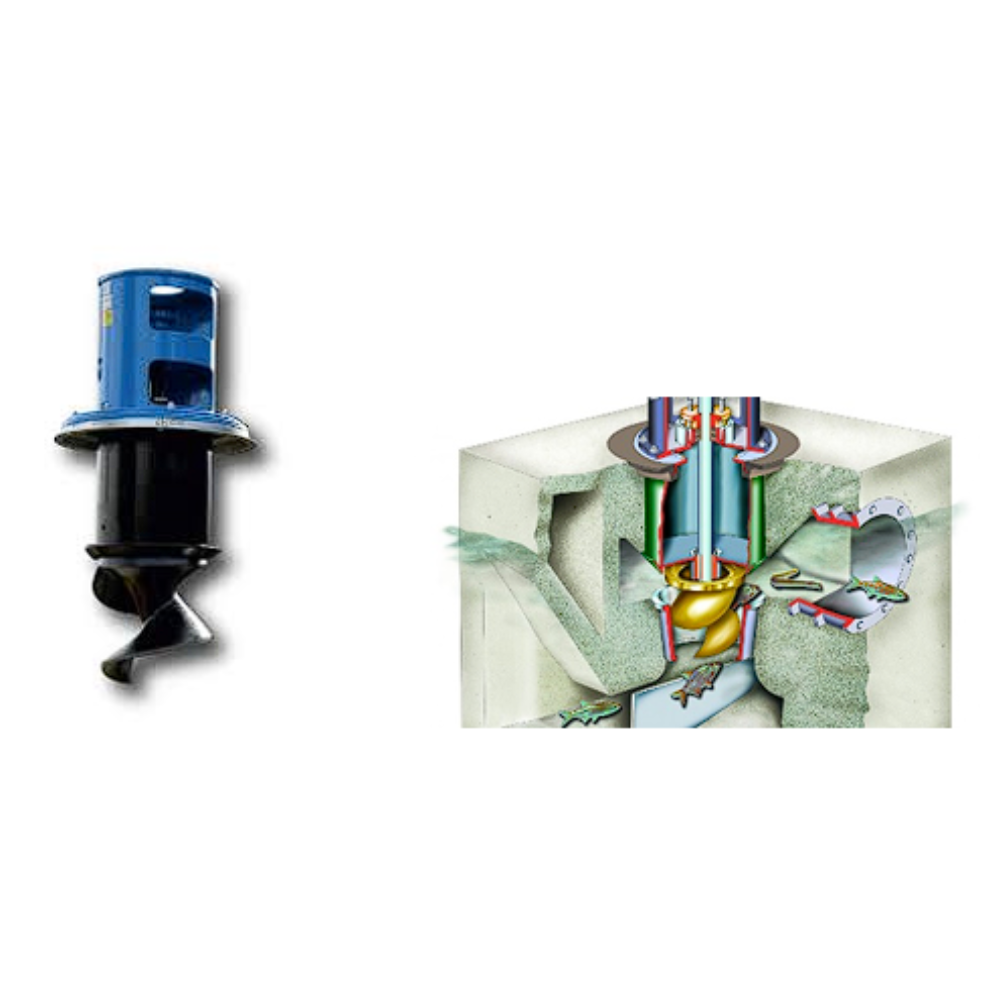

The BVOP is a high-quality axial propeller pump with impressive performances, a high quality and a relatively low noise level. Bosman Watermanagement made use of its many years’ experience in the development of the BVOP pump for the discharge of water from and/ or management of the water level in polders and low-lying areas, and for supply of make-up water to canals with locks and in areas at higher altitudes in dry periods.

This pump with a range of seven standard modules, is available with capacities of 12 to 360 m3/minute with a delivery head of approximately 10 meters. The combination of a performed suction chamber with adjustable impeller blades and a spiral guide in a very generously-sized concrete volute achieves an ideal flow pattern with minimum losses and a large passage. Consequently, this design of this pump achieves a high efficiency. In addition, the pump requires only a shallow sub-mergence depth.

Three impeller configurations for each size of pump guarantee optimum performance without harmful cavitation or vibration zones.

The most suitable type of pump for specific application is determined using CAS (Computer Aided Selection). When selecting a pump type the specified duty point (flow/delivery head) needs to be realised. The minimum and maximum static delivery heads, the location of the optimum efficiency point, the NPSH etc. are additional factors that need to be taken into account when selecting a pump

Once a selection has been made, the CAS system will present the calculated pump curve and the desirable guarantee point.

Features & Benefits of the BVOP pump

• Low, fixed operating costs

• Extremely reliable pumping concept (no problems for many years)

• The pump’s special hydraulic design virtually precludes blockages

• No corrosion due to the concrete technology used for the pump

• No bend required, since the bend is integrated in the concept

• Removable inner components

• Standard driving components

• Low energy costs (high pump efficiency)

• Extremely low noise levels

• Easy to maintain

• The inner components can be removed from the pump for inspection without needing to drain the pumping station