DWA Water & Wastewater Treatment Equipment

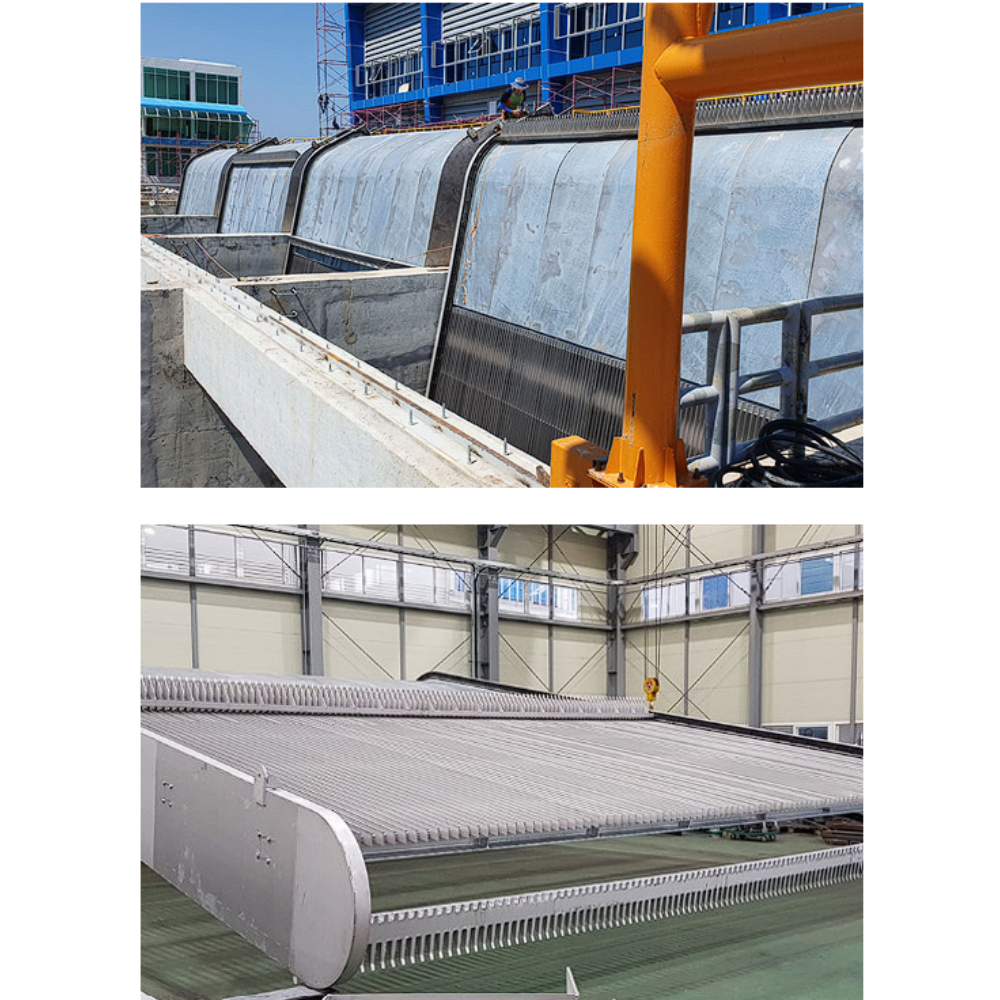

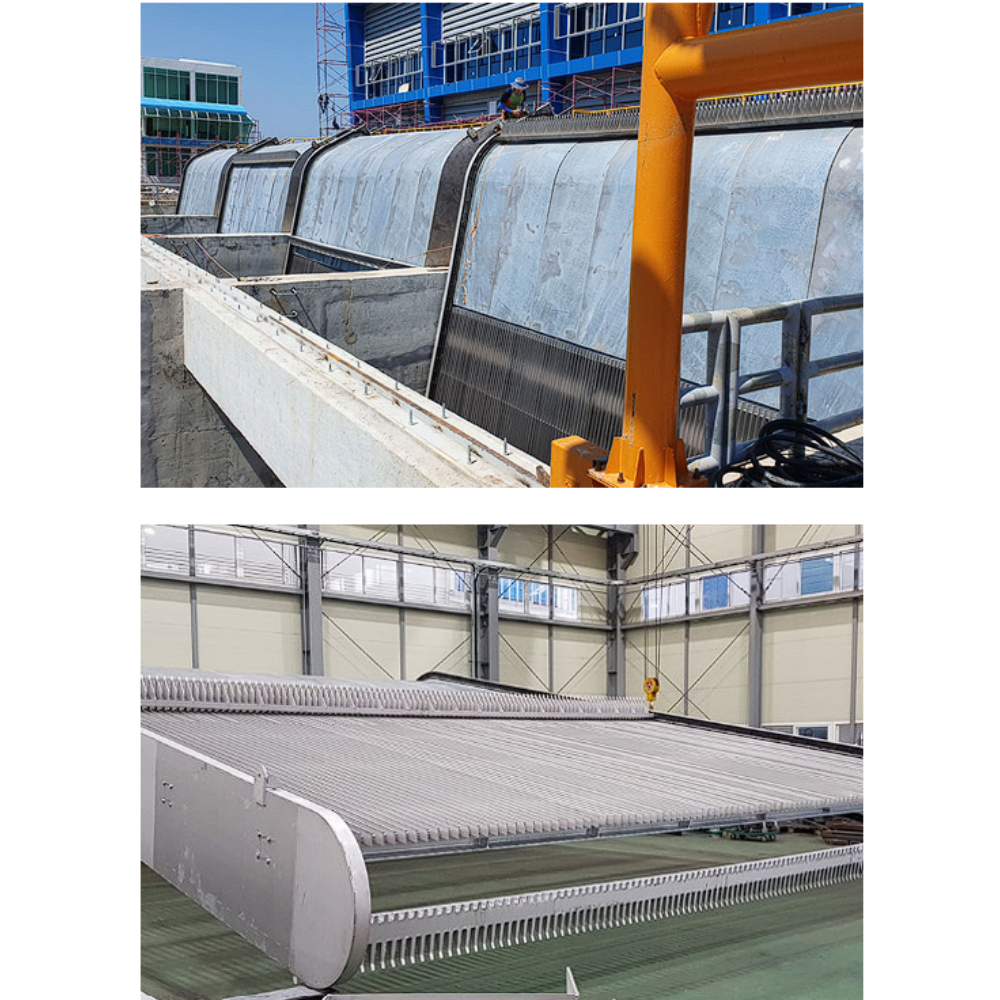

DWA, DOWON APEX CORPORATION is a professional manufacturer that designs and fabricates advanced water & wastewater treatment equipment in South Korea; which includes: metal or non-metal chain flight sludge scraper systems, rotary automatic bar screens, mechanical coarse & fine bar screens, automatic grab screens, travelling bridge scraper systems, bridge sludge collectors, band screens, cake hoppers, belt & screw conveyors at water, sewer and wastewater treatment plants in 15 countries worldwide.

Other than that, DWA also designs and fabricates advanced incinerator plants for hazardous and municipal wastes in these countries: South Korea, Russia, Iraq and Iran.